Background

Anglia Steel Industries Ltd. established its headquarters in Calgary in 1984 and has been supplying steel framework for various industries in Western Canada to this day. Many shopping centres, schools, office buildings and warehouses depend on Anglia’s quality work and dependable service.

Challenge

With a fleet of 13 vehicles transporting fabricated metal products to customer work sites, Anglia Steel was looking to employ a monitoring system that could help track vehicles, provide additional safety to employees traveling in rural areas and control escalating fuel costs. Having cultivated a sterling reputation for timely deliveries and a commitment to customer service, it also wanted a system that could help automate its delivery process and improve its on-time performance.

„We also knew that our fuel costs were higher than they could be, but didn’t know exactly how to best improve this issue“

– Terence Schofield , Safety Officer at Anglia Steel

“In keeping with our reputation for strong customer service, we wanted to improve our tracking capabilities over our fleet. This would help to shorten delivery windows and ensure our customer deliveries were as efficient as possible,” noted Terence Schofield, Safety Officer at Anglia Steel. “We thought that any tracking system that could do what we wanted would cost thousands and thousands of dollars a month and just wouldn’t be worth the investment.”

Solution

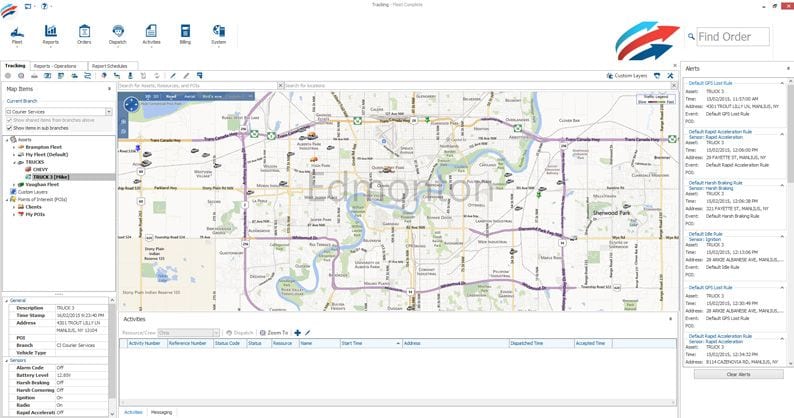

Anglia Steel worked with Fleet Complete to deploy a real-time fleet management and tracking solution. Anglia Steel is taking full advantage of the Web-based solution to help streamline operations and boost productivity. “With the quick and smooth product installation, we were able to easily implement Fleet Complete into our daily operations,” says Schofield.

„While it is fully customizable, it is also user-friendly and is created with the average person in mind. During the first few weeks, I worked on remote access with my sales representative to ensure it was working to best meet my company’s needs.“

– Terence Schofield

The Fleet Complete hardware is mounted and hidden within the dashboard in all 13 vehicles, from Anglia’s large welding trucks to its delivery vehicles. Schofield accesses the software through a variety of channels to ensure updates can be monitored remotely, from office computers, laptops with wireless signals, to mobile devices when on job sites. Schofield is able to track vehicle location and speed as well as accurately plan the most efficient routes from point A to B.

Benefits

With Fleet Complete in place, Anglia Steel is realizing a host of business benefits. The company can now easily look-up vehicle location and status in real-time, helping provide up-to-the-minute insight into its fleet and offer an extra degree of driver safety. By utilizing Fleet Complete’s reports on driver behaviour, Terence Schofield is able to capture more accurate information on speeds and time flow to assist in new customer quoting and up-to-minute delivery-based information.

„The ability to keep a better handle on our fleet locations at all times helps us better track the driver hours to reduce the amount of overtime as well as ensure a more effective resource planning and allocation. Since drivers often visit remote locations and drive during off-peak hours, Fleet Complete also provides us with an added level of safety for our employees.“

– Terence Schofield

Anglia Steel is making use of Fleet Complete’s enhanced reporting features to increase efficiency and reduce costs. Having a greater insight into daily driver speeds and driver activity, the company was able to implement new policies for driving speed and activity, while maintaining delivery schedules that led to a 10% reduction in fuel costs. “Using Fleet Complete has essentially paid for itself time and time again. Reducing our fuel costs has an obvious and immediate impact to our bottom line,” says Schofield.

“We currently have 13 vehicles with the Fleet Complete solution installed. We’ve since had two vehicles stolen and one in an accident. We’ve been able to recover all three vehicles using the GPS tracking capabilities,” says Schofield. “Our immediate ROI with Fleet Complete has been huge. In the past, we may not have even found these vehicles for months, which would have cost us around $160,000 to replace.”

The company is also using Fleet Complete to help reduce maintenance costs by establishing rules for vehicles in terms of the optimal amount of operation hours between services. For a growing company, reduction of these expenses has a significant impact on company’s success and future prosperity.

„Our immediate ROI with Fleet Complete has been huge. In the past, we may not have even found [lost or stolen] vehicles for months which would have cost us around $160,000 to replace.“

– Terence Schofield, Safety Officer

Our immediate ROI with Fleet Complete has been huge. In the past, we may not have even found [lost or stolen] vehicles for months which would have cost us around $160,000 to replace.

Terence Schofield,Safety Officer

- Manufacturer of fabricated metal materials

- Used Fleet Tracker with custom integration

- Fleet of 13 vehicles

- Returned $160,000 in stolen vehicle recovery

- Reduced fuel expenses by 10%

Powering sustainable fleets!

Få et klart overblik over alle dine værdigenstande!